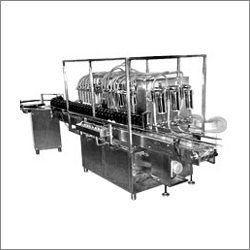

Liquid Filling Line

MOQ : 1 Unit

Liquid Filling Line Specification

- Product Type

- Liquid Filling Line

- Material

- Stainless Steel (SS304/SS316)

- Application

- Pharmaceutical, Food, Chemical, and Beverage Industries

- Packaging Material

- Bottle, Glass, Pet, HDPE, etc.

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Weight (kg)

- Approx. 800 kg

- Dimension (L*W*H)

- 2260 mm x 920 mm x 1500 mm

- Capacity

- 30 to 150 Bottles per minute (variable)

- Color

- Metallic Silver

Liquid Filling Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Packaging Details

- According to product

- Main Domestic Market

- All India

About Liquid Filling Line

We are a reputed name in the industry, devoted towards offering the best quality Liquid Filling Line. With the help of pioneering techniques, the provided line is manufactured under the supervision of adept professionals. It is widely used for filling milk, oil, ointment, shampoo, juice etc. In addition to this, the offered Liquid Filling Line can be bought from us at market leading prices by our prestigious clients.

Key Points:

- Require less maintenance

- High strength

- Longer service life

- Less power consumption

Advanced PLC-Based Operation

Our filling line integrates advanced PLC controls, offering superior precision, consistent operation, and minimized human intervention. Computerized settings enable easy adjustments for different bottle sizes and fill volumes, ensuring optimal results and reducing wastage during batch changes.

Engineered with Premium Stainless Steel

Constructed from SS304/SS316-grade stainless steel, this liquid filling line guarantees exceptional durability and corrosion resistance. Its robust build ensures hygiene compliance for the pharmaceutical and food industries, while ensuring longevity and ease of cleaning in demanding production environments.

High Throughput and Versatility

With the ability to fill 30 to 150 bottles per minute, this line adapts swiftly to varying production needs. Whether handling glass, PET, or HDPE bottles, it accommodates multiple packaging types and sizes, ensuring maximum flexibility for changing market demands.

FAQs of Liquid Filling Line:

Q: How does the PLC control system enhance the operation of the liquid filling line?

A: The PLC (Programmable Logic Controller) enables precise, computerized management of the filling process, ensuring consistent fill volumes, easy parameter adjustments, and integration with other line equipment. This reduces manual intervention and potential errors, improving overall production accuracy and efficiency.Q: What types of bottles and materials can this filling line handle?

A: The machine is designed to accommodate a range of bottle materials, including glass, PET, and HDPE, making it suitable for varied packaging requirements in different industries. It adjusts easily to different bottle shapes and sizes, providing greater operational flexibility.Q: Where is this liquid filling line most commonly used?

A: This filling line is widely utilized in pharmaceutical, food, chemical, and beverage industries, where hygienic processes and accurate filling are critical. Its stainless steel construction makes it ideal for sensitive and large-scale production environments.Q: What is the typical installation process for this equipment?

A: The installation involves positioning the unit as per the dimensions (2260 mm x 920 mm x 1500 mm), connecting the electric drive, configuring the PLC controls, and running initial calibration. Manufacturers or suppliers in India usually provide support for setup and operator training.Q: When should you use an automatic liquid filling line instead of a manual system?

A: An automatic liquid filling line is recommended for medium to large-scale production where high speed, accuracy, hygiene, and minimal operator intervention are required. It is especially beneficial when consistent output and regulatory compliance are necessary.Q: What are the key benefits of using stainless steel (SS304/SS316) construction?

A: SS304/SS316 stainless steel ensures excellent resistance to corrosion, ease of cleaning, and robust durabilityan essential combination for the rigorous standards of food and pharmaceutical production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free