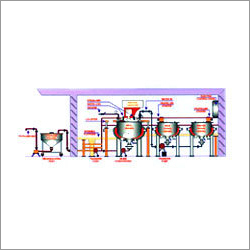

Cream Manufacturing Plant

MOQ : 1 Unit

Cream Manufacturing Plant Specification

- Driven Type

- Motor Driven

- Accessories

- Homogenizer, Vacuum Pump, Agitator, Emulsifier, Control Panel, CIP System

- Usage & Applications

- Manufacturing Cosmetic Creams, Pharmaceutical Ointments, Lotions, Food Pastes

- Efficiency (%)

- 95%

- Motor Power

- 5 HP (customizable)

- Automation Grade

- Fully Automatic

- Speed

- Variable (up to 3000 rpm)

- Temperature Range

- Ambient to 120C

- Type

- Cream Manufacturing Plant

- Material

- Stainless Steel (SS304/SS316)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Control Panel

- Drive Type

- Electric

- Dimension (L*W*H)

- 3000 mm x 2200 mm x 2500 mm (approx.)

- Color

- Silver

- Capacity

- 100 L to 1000 L per batch

- Features

- Homogenizer, Heating & Cooling System, Emulsification, Vacuum Pump, CIP Cleaning System

- Machine Type

- Automatic Cream Mixer & Processor

- Surface Finish

- Mirror Polished

Cream Manufacturing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Packaging Details

- According to product

- Main Domestic Market

- All India

About Cream Manufacturing Plant

Being an eminent organization in the industry, we are involved in providing a premium quality range of Cream Manufacturing Plant. The offered plant is ideal tool for the pharmaceutical and cosmetic industries for the production of Ointment, Cream, Lotions, Tooth Paste & other emulsions/ homogenization. With the aid of latest techniques and pristine grade components, the provided plant is manufactured by a team of our ingenious professionals. Our valuable clients can avail this Cream Manufacturing Plant from us at market leading prices.

Key Points:

- Excellent operational life

- Easy to install

- Precisely engineered

- Less power consumption

Cutting-Edge Automation for Consistent Quality

Leverage advanced PLC-based control panels and automatic operation to ensure uniform batch production. The systems automation streamlines mixing, heating, and cooling processes, resulting in high-quality creams and ointments with minimal manual intervention. Enjoy precise process control and rapid changeover times.

Versatility in Applications and Capacities

Designed for a diverse range of industries, our plant produces cosmetic creams, pharmaceutical ointments, lotions, and food pastes. With batch capacities from 100 to 1000 liters, its ideal for both large-scale manufacturers and custom processors, ensuring productivity across multiple applications.

Superior Hygiene and Easy Maintenance

Constructed with SS304/SS316 stainless steel and featuring a mirror-polished surface, the plant ensures excellent hygiene standards. The integrated CIP (Clean-In-Place) system simplifies cleaning and decreases downtime, maintaining product integrity and regulatory compliance.

FAQs of Cream Manufacturing Plant:

Q: How does the Cream Manufacturing Plant ensure consistent product quality?

A: The plant uses a PLC-based control panel to automate processes and control parameters such as temperature, mixing speed, and timing. The built-in homogenizer and emulsifier guarantee uniform mixing and texture, while the heating and cooling systems regulate temperature for optimal product consistency.Q: What types of products can be manufactured using this Cream Manufacturing Plant?

A: This plant is designed for the production of cosmetic creams, pharmaceutical ointments, lotions, and food pastes. Its versatile configuration supports a range of viscosities and formulations, making it suitable for both cosmetic and food industry applications.Q: When should the CIP (Clean-In-Place) system be used in the production process?

A: The CIP system should be used after each batch or production run to ensure complete removal of residues and contaminants. This not only maintains hygiene and product quality but also minimizes downtime between batches.Q: Where is this Cream Manufacturing Plant typically installed?

A: The plant is commonly installed in manufacturing units, pharmaceutical companies, cosmetic production facilities, and food processing plants across India. Its compact dimensions (3000 mm x 2200 mm x 2500 mm) allow for flexible installation in spaces with adequate utilities.Q: What is the process involved in making creams and ointments using this plant?

A: Raw materials are loaded into the mixing vessel, where they are homogenized and emulsified at controlled speeds and temperatures. The automatic control system manages heating or cooling as required. When processing is complete, the CIP system is utilized for cleaning.Q: How can manufacturers benefit from using this automatic plant?

A: Manufacturers benefit from improved product quality, high efficiency (up to 95%), reduced labor costs, and consistent batch results. The automatic operation, rapid process cycles, and easy maintenance increase productivity and streamline regulatory compliance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free